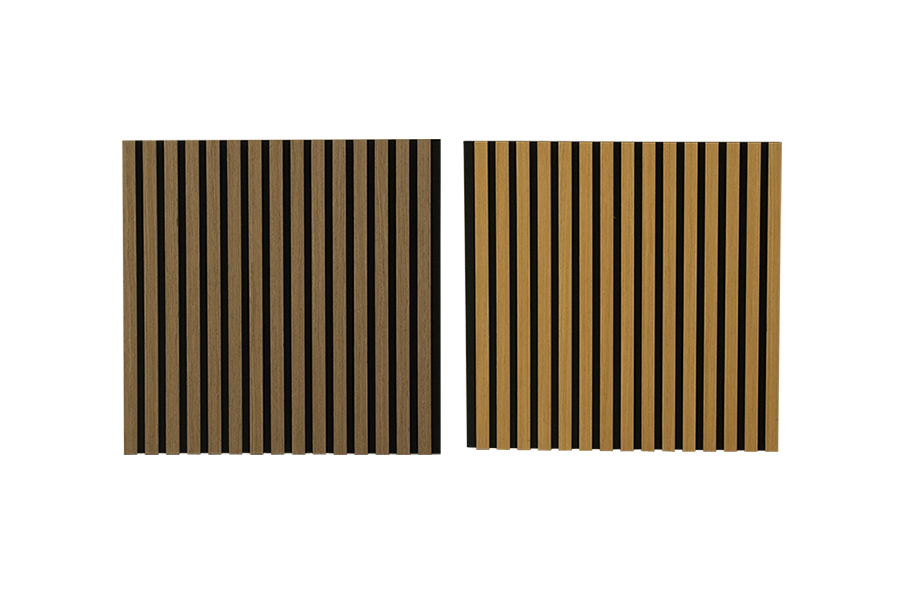

As urban environments grow denser and noise pollution becomes a greater concern, architects and builders are increasingly turning to innovative materials for sound control. Among these, wood plastic composite panel solutions are gaining attention for their unique combination of acoustic performance and structural benefits. But how effective are WPC board panel systems at blocking sound transmission, and where do they fit in modern construction?

Understanding Sound Transmission in Building Materials

Sound transmission class (STC) ratings measure how well a material reduces airborne noise, with higher numbers indicating better performance. Traditional materials like concrete and drywall have established ratings, but newer WPC building materials present an interesting alternative. These hybrid panels combine wood fibers with thermoplastics to create products that offer both the natural aesthetics of wood and enhanced functional properties.

The acoustic performance of wood plastic composite panel systems depends on several factors:

- Material density and thickness

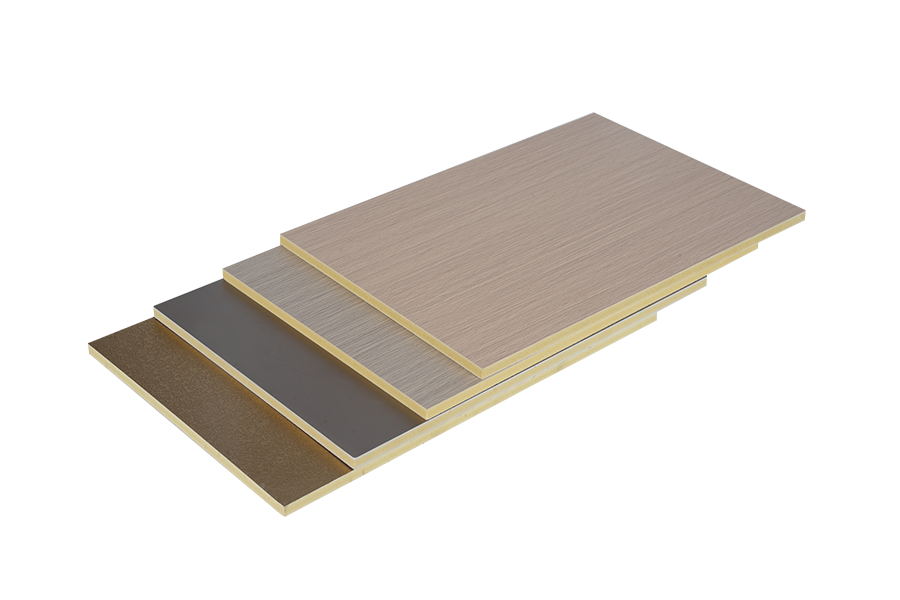

- Internal composition and layering

- Installation methods and edge sealing

- Surface treatments and finishes

How WPC Panels Perform Acoustically

When tested against conventional materials, WPC board panel solutions typically achieve STC ratings between 25 and 35, placing them in the mid-range of sound blocking performance. While they don't match the mass-loaded properties of concrete (STC 50+), they outperform many lightweight partition systems. The secret lies in the composite's unique structure - the wood fibers create natural sound-absorbing pathways while the plastic matrix provides structural stability.

Optimizing WPC for Sound Control

Manufacturers have developed several techniques to enhance the acoustic performance of WPC board panel products:

1. Increased Density - By adjusting the wood-to-plastic ratio and adding mineral fillers, some WPC building materials achieve better sound blocking through increased mass.

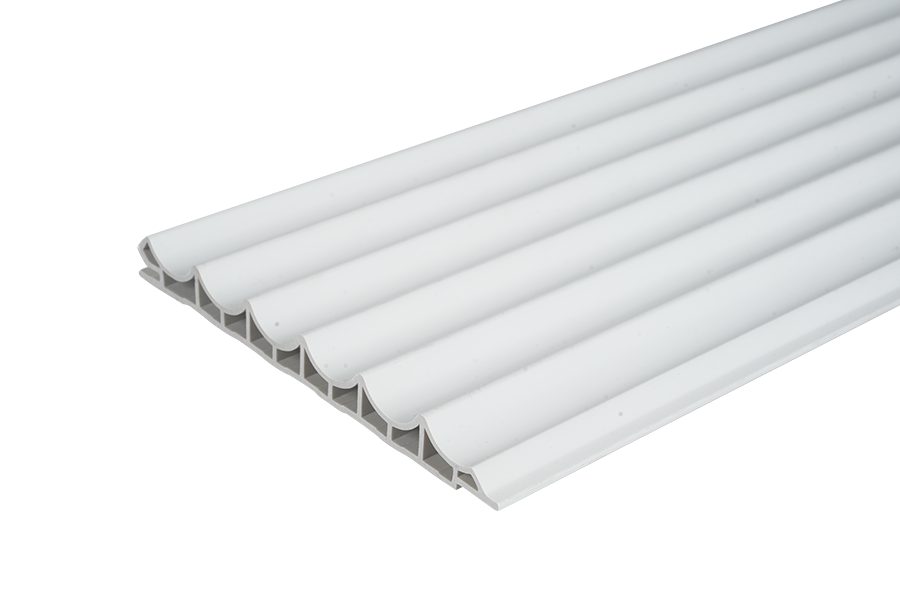

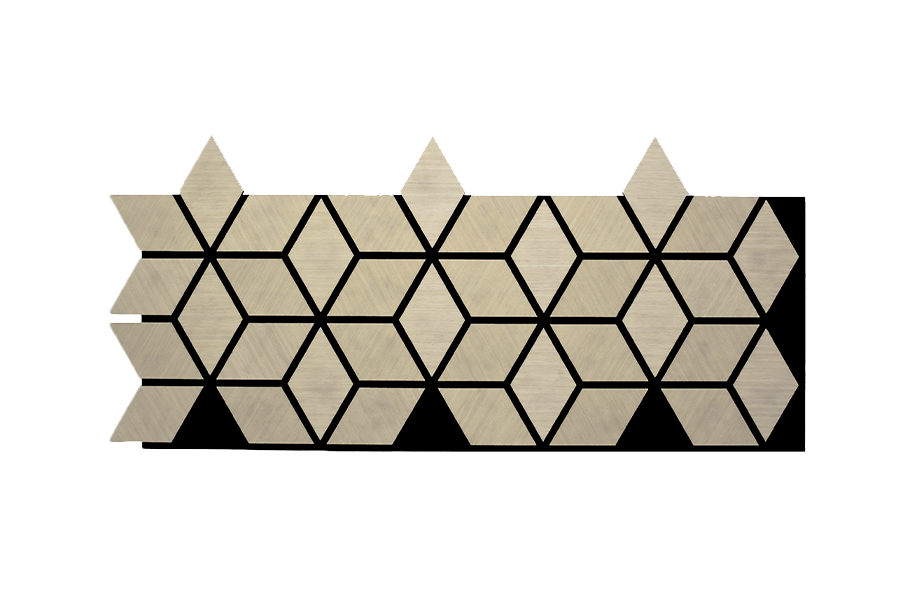

2. Perforated Designs - Certain wood plastic composite panel variants feature precisely engineered perforations that help trap and dissipate sound waves.

3. Sandwich Construction - Multi-layer WPC board panel systems with sound-absorbing cores can significantly improve STC ratings while maintaining the material's signature durability.

4. Resilient Mounting - When installed with specialized clips and channels, WPC building materials can achieve better sound isolation than rigidly mounted panels.

Practical Applications in Modern Construction

The balanced acoustic properties of wood plastic composite panel systems make them particularly suitable for:

- Office partitions where moderate sound privacy is needed without the weight of concrete

- Residential interior walls in multi-family housing projects

- Educational facilities requiring durable, sound-dampening surfaces

- Hospitality spaces that benefit from both acoustic performance and aesthetic appeal

Unlike traditional WPC board panel uses in decking and cladding, these acoustic applications highlight the material's versatility. Architects appreciate how WPC building materials can serve multiple functions - structure, finish, and sound control in one system.

Comparing WPC to Alternative Acoustic Materials

While specialized acoustic products like mineral wool panels or mass-loaded vinyl offer higher STC ratings, wood plastic composite panel solutions provide distinct advantages:

- Moisture resistance outstanding to many sound-absorbing materials

- Structural integrity that eliminates the need for separate framing in some applications

- Maintenance benefits compared to fabric-wrapped acoustic panels

- Design flexibility with wood-like finishes that blend seamlessly with interiors

For projects where moderate sound control is needed alongside durability and aesthetic requirements, WPC board panel systems present a compelling option. The development of specialized WPC building materials with enhanced acoustic properties continues to expand their suitable applications.

Future Developments in WPC Acoustics

Material scientists are working on next-generation wood plastic composite panel formulations that could push STC ratings higher while maintaining the material's other benefits. Areas of innovation include:

- Nano-composite additives that improve sound blocking without adding weight

- Micro-perforation patterns optimized for specific frequency ranges

- Hybrid assemblies combining WPC board panel surfaces with other acoustic materials

As these advancements mature, we may see WPC building materials competing with traditional acoustic solutions in more demanding environments while retaining their signature advantages of weather resistance and low maintenance.

Español

Español عربى

عربى русский

русский