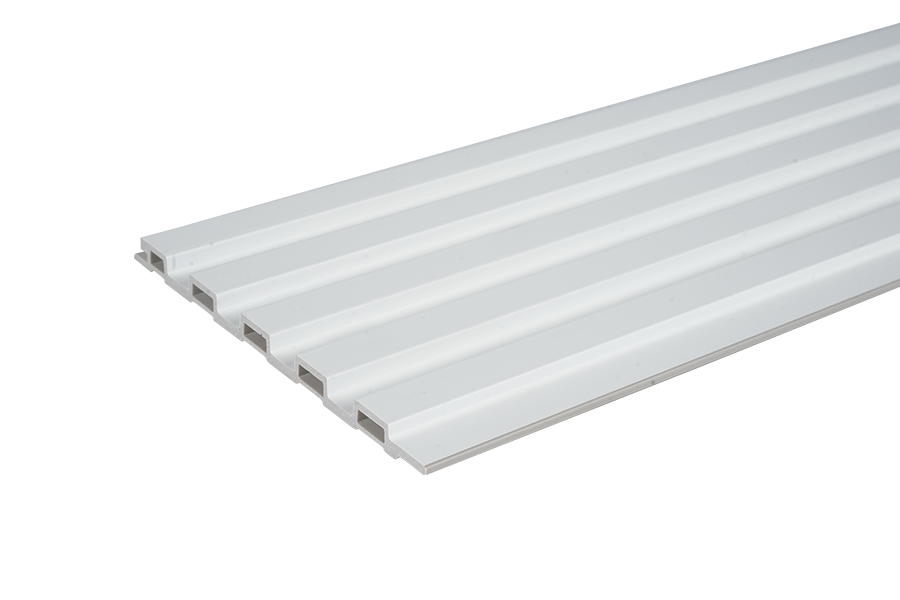

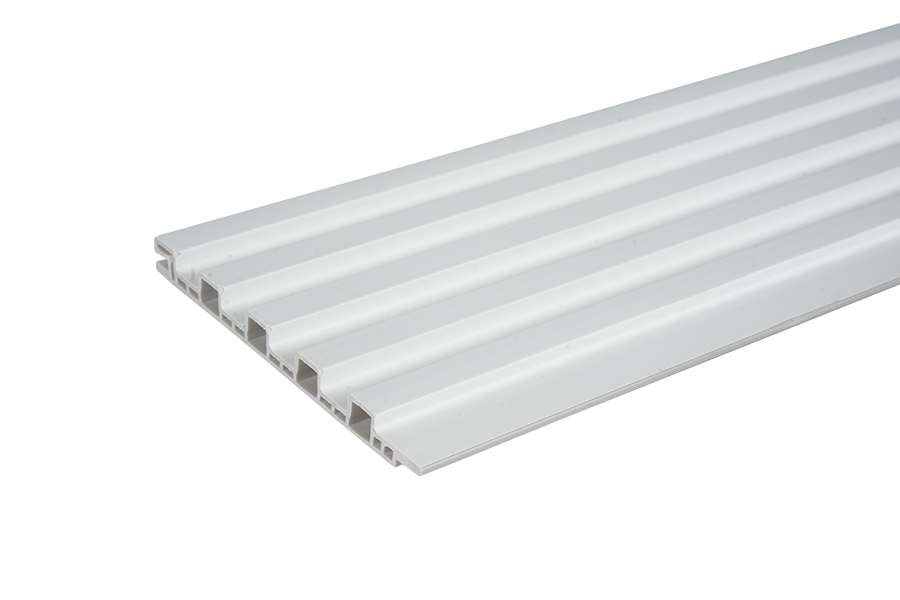

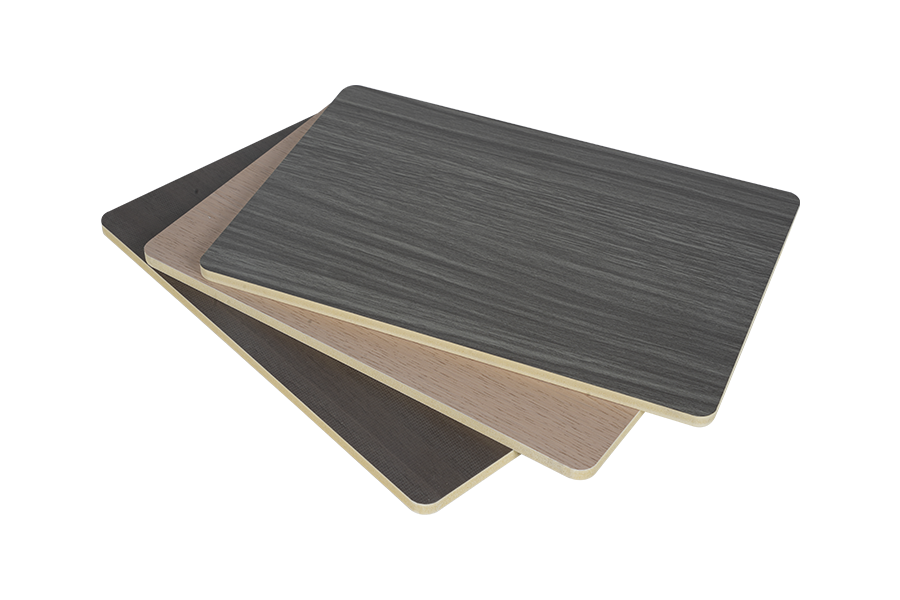

Wood plastic composite material is a composite material made from wood fibers or wood flour and thermoplastic polymers. It offers a range of advantages over traditional wood, such as resistance to moisture, fungi, and insects, making it an ideal choice for outdoor applications. Moreover, WPC's composition allows for a wide range of colors and finishes, opening up creative possibilities for designers and fabricators alike.

Choosing the Right CNC Machine

When it comes to carving intricate patterns into wood plastic composite material, the choice of CNC machine is critical. A high-quality CNC router with precision movements and a powerful spindle is essential. The machine should be capable of handling the specific hardness and density of WPC. It's also important to ensure that the CNC router has a spindle that can reach the required RPM for the task, as WPC can be more resistant to cutting than traditional wood.

Selecting the Appropriate Tooling

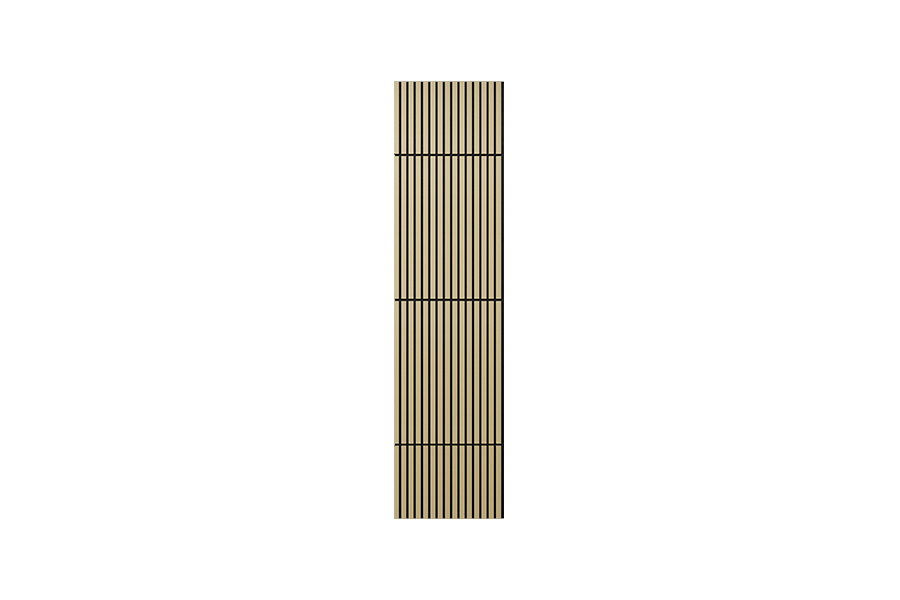

The choice of cutting tools is another crucial aspect of CNC carving in WPC. Carbide-tipped bits are generally recommended for their hardness and durability when cutting through the composite material. The shape and size of the bit should match the intricacy of the patterns being carved. Smaller bits are ideal for fine details, while larger bits can be used for broader, more sweeping cuts in wood plastic composite material.

Optimizing CNC Settings

To achieve results when carving intricate patterns in wood plastic composite, it's essential to optimize the CNC machine settings. Feed rates should be adjusted to account for the material's resistance; too fast, and the machine may skip or burn the surface, too slow, and the process will be inefficient. Similarly, the depth of cut must be carefully controlled to ensure that the pattern is cleanly and accurately executed without damaging the WPC board.

Coolant and Lubrication

Using a coolant or lubricant can significantly improve the CNC carving process in wood plastic composite material. A water-based coolant can help to dissipate heat generated during the cutting process, reducing the risk of burning or melting the material. Additionally, a lubricant can reduce friction between the cutting tool and the WPC, cause a smoother finish and longer tool life.

Path Planning

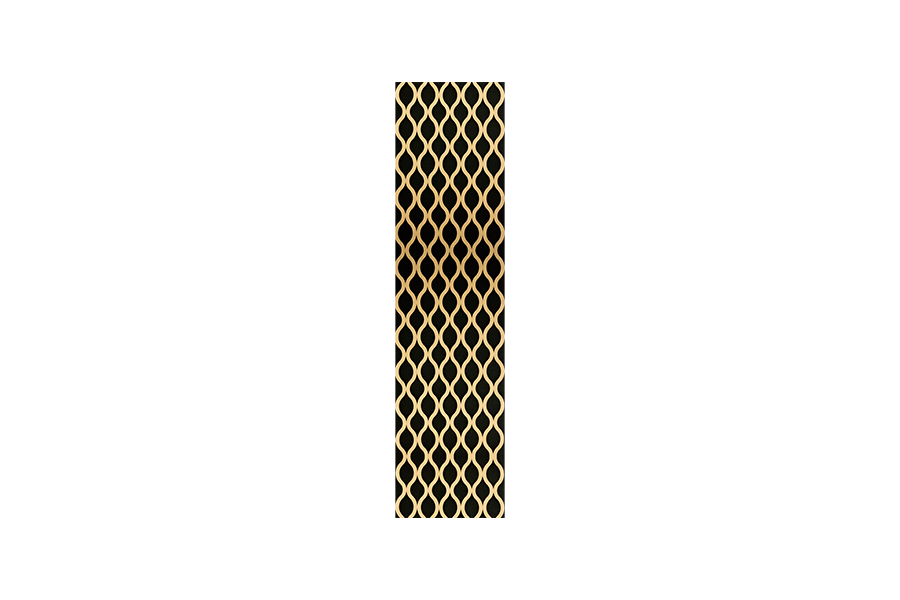

Effective path planning is crucial for intricate patterns in wood plastic composite material. The CNC software should be used to create a tool path that minimizes the number of passes required, as each pass can potentially introduce errors or inaccuracies. Contour cutting should be prioritized where possible, as it tends to produce cleaner, more accurate results than pocketing in WPC.

Bit Engagement and Exit Strategy

When carving intricate patterns in wood plastic composite, it's important to consider the bit's engagement and exit points. A smooth entry and exit can prevent tear-out and ensure a clean finish. This is particularly important in WPC, as the material's composite nature can make it more susceptible to damage if the bit exits too aggressively.

Post-Processing

After the CNC carving process, post-processing is often necessary to achieve a good finish in wood plastic composite material. This may involve hand-sanding the edges to remove any burrs or rough spots, followed by a polishing compound to achieve a high-gloss finish. In some cases, a clear coat may be applied to protect the WPC board and enhance its appearance.

Carving intricate patterns in wood plastic composite material is an art that requires precision, the right tools, and a deep understanding of the material's properties. By following these CNC carving tips, fabricators can achieve stunning results with WPC, pushing the boundaries of what's possible in woodworking and fabrication. As the demand for wood plastic composite continues to grow, so too will the need for skilled operators who can bring complex designs to life in this versatile material.

Español

Español عربى

عربى русский

русский