When it comes to wall protection in high-traffic environments, WPC crash-proof boards are an increasingly popular choice due to their balance of strength, aesthetics, and environmental friendliness. But beyond the surface-level benefits, it’s crucial to understand how WPC crash-proof boards work. In this article, we will explore the core principles behind their impact resistance, focusing on how they absorb shock, their compressive and bending strength, and how the method of installation can influence performance.

How Do WPC Crash Proof Boards Absorb Impact Energy?

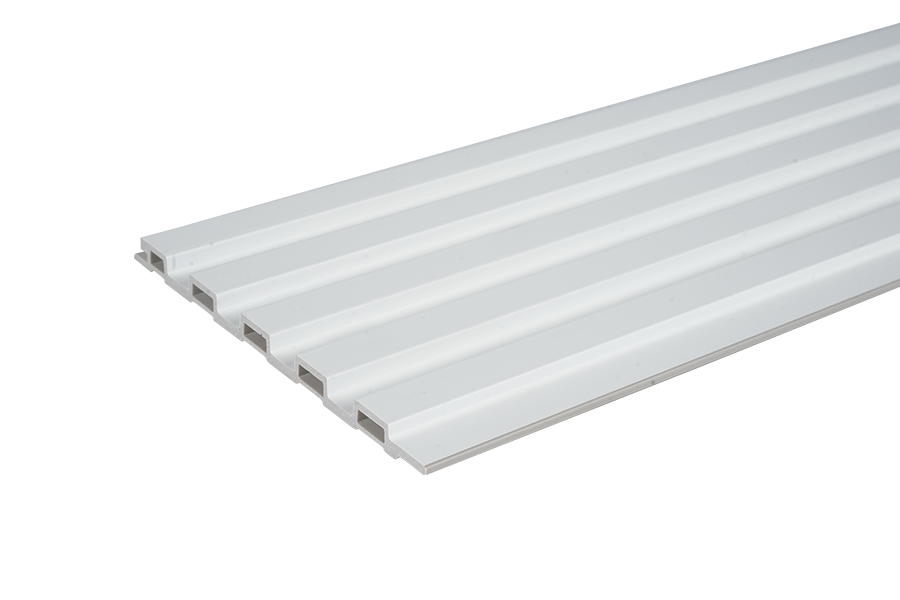

The primary function of a WPC crash-proof board is to protect walls and corners from damage caused by trolleys, hospital beds, carts, or even wheelchairs. This is achieved through the board’s unique structure, which is composed of a wood-plastic composite (WPC) core that combines plastic polymers with natural wood fibers.

When a force is applied to the surface of a WPC crash proof board, the energy is distributed across the panel rather than being concentrated at a single point. The composite structure absorbs a significant portion of the impact energy through elastic and plastic deformation. Unlike solid plastic panels that may crack or deform permanently, a WPC crash proof board flexes slightly under pressure and then returns to its original shape, which minimizes visible damage.

Compressive and Bending Strength: The Backbone of Performance

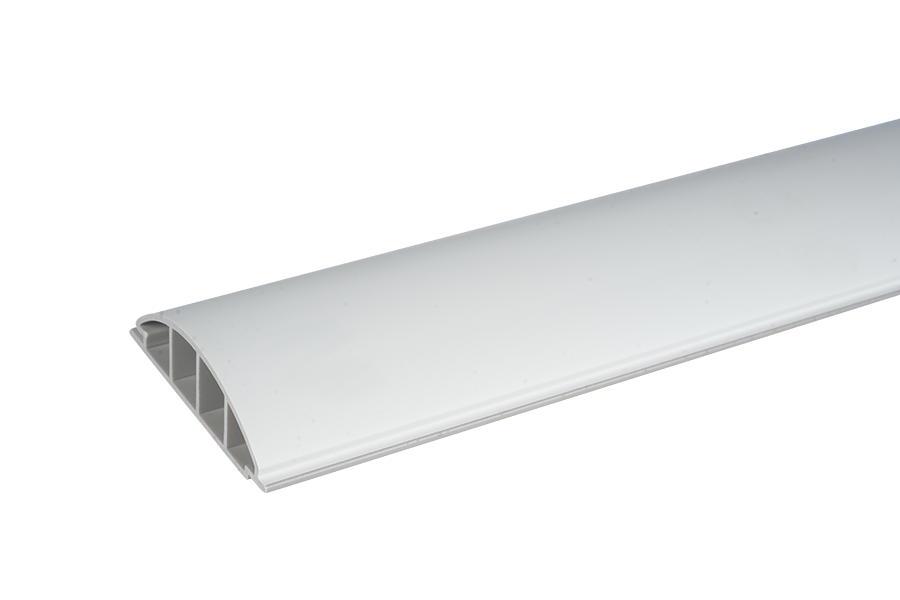

A WPC crash proof board is designed to withstand both compressive and bending forces. These mechanical properties are vital in ensuring the product performs under real-world conditions.

The compressive strength of a WPC crash proof board allows it to resist pressure applied perpendicularly to its surface. This is essential in environments like hospitals or educational institutions, where the panels might be subjected to repeated contact from carts or equipment. The board’s ability to maintain structural integrity under such pressure directly contributes to its long-term durability.

Equally important is its bending strength, which reflects how much the board can flex without breaking when a force is applied along its length. In practice, this means a WPC crash proof board can endure horizontal impacts, such as a sideways push from a wheelchair, without cracking or detaching from the wall.

The high performance of WPC crash proof boards in both compression and bending tests is a result of their optimized composition. The ratio of wood fibers to plastic, along with manufacturing techniques such as extrusion, contributes to a balanced structure that performs reliably in different environments.

The Role of Installation in Maximizing Impact Resistance

Even the highest-quality WPC crash proof board can underperform if not installed correctly. The method of attachment, the quality of the wall surface, and the type of mounting hardware used all play significant roles in how well the board can absorb impact and maintain its position.

For optimal performance, WPC crash proof boards should be installed on clean, flat surfaces using heavy-duty adhesive and mechanical fasteners where needed. Improper installation may lead to gaps behind the board, which can compromise its ability to absorb shock effectively. If a WPC crash proof board is loosely mounted, it may flex too much upon impact, causing cracks or detachment over time.

Additionally, the height and spacing of the boards should be carefully planned based on the specific type of environment and the expected level of traffic. In areas where trolleys and beds frequently come into contact with walls, placing WPC crash proof boards at the correct height ensures the most vulnerable parts of the wall are adequately protected.

The performance of WPC crash proof boards in real-world settings is rooted in a well-engineered combination of material science and installation techniques. Their ability to absorb impact energy, along with high compressive and bending strength, makes them a dependable choice for long-term wall protection. However, to fully leverage the benefits of WPC crash proof boards, proper installation is essential.

From hospitals and clinics to schools and public buildings, WPC crash proof boards continue to provide reliable protection while maintaining a clean, professional appearance. Understanding how they work not only helps in selecting the right product but also ensures optimal use and longevity in any application.

Español

Español عربى

عربى русский

русский