In recent years, SPC board has gained attention as a reliable material for construction and interior design. It is widely used in flooring, wall cladding, and other decorative applications due to its durability and functional properties. To better understand its role in modern building projects, it is important to explore what an SPC board is, what it is made of, and how it differs from traditional PVC or WPC boards.

What Is an SPC Board?

An SPC board is a type of engineered material known as Stone Plastic Composite board. It is designed to provide strength, dimensional stability, and resistance to environmental factors such as moisture and temperature changes. The main appeal of an SPC board lies in its ability to combine the benefits of both natural minerals and polymers, creating a product that is versatile and suitable for residential as well as commercial applications.

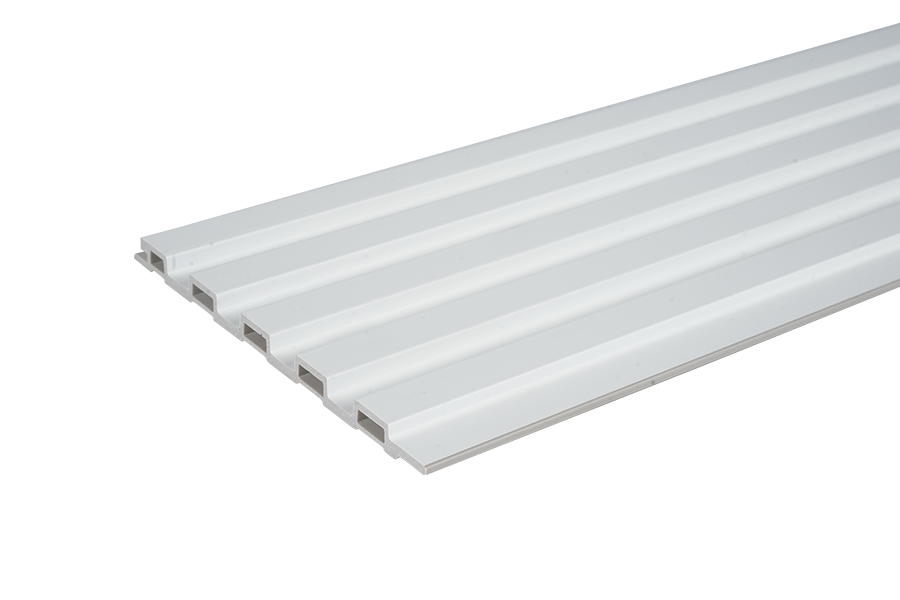

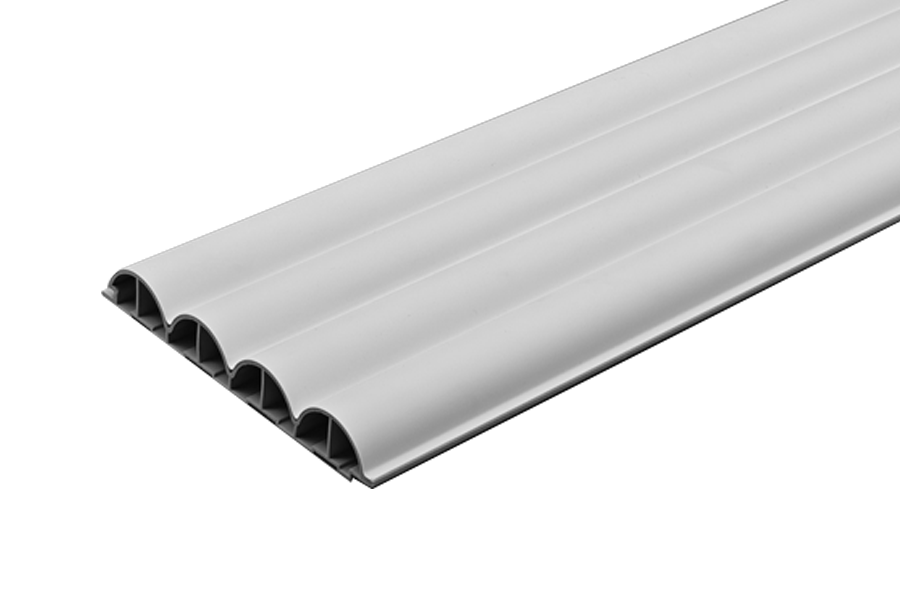

SPC boards are commonly used in flooring, where their rigid structure supports heavy use, but they are also applied in wall panels, ceilings, and furniture production. Their uniform structure makes them easy to install, while the surface can be finished with a variety of decorative layers to achieve wood, stone, or custom textures.

What Is SPC Made Of?

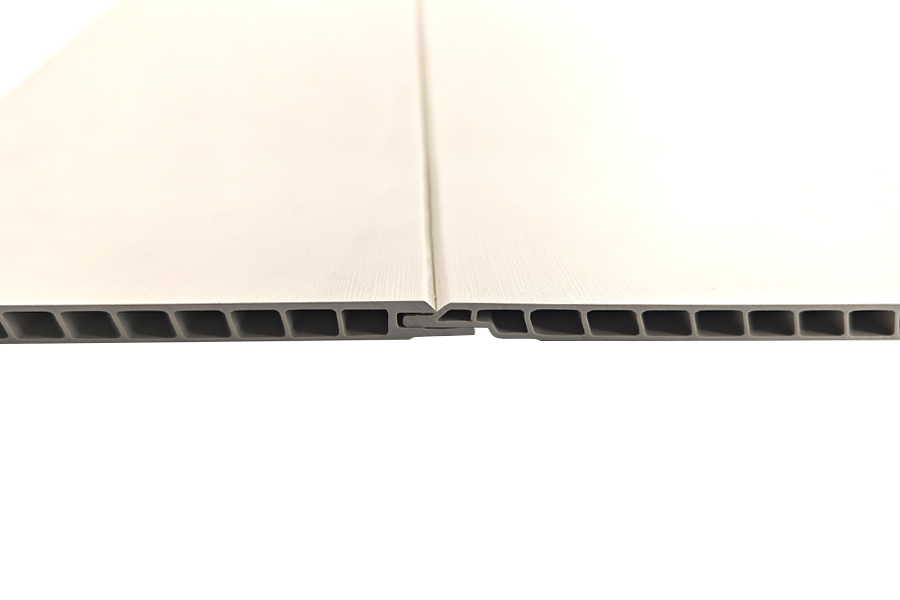

The composition of an SPC board is central to its performance. The core layer is typically made of natural limestone powder combined with polyvinyl chloride (PVC) and stabilizers. This mixture creates a dense and rigid board that is resistant to warping and expansion. The stone component contributes to hardness and stability, while the polymer element provides flexibility and resilience.

Many SPC boards also include multiple layers:

Wear Layer: A protective coating that resists scratches and stains.

Decorative Film: A printed layer that provides realistic wood, stone, or custom designs.

SPC Core: The rigid middle layer composed of limestone and PVC.

Backing Layer: Designed to enhance stability and sound absorption.

This layered structure ensures that an SPC board is not only visually appealing but also practical for high-traffic and moisture-prone areas.

How Is an SPC Board Different from Traditional PVC or WPC Boards?

While SPC board shares some similarities with PVC and WPC, there are important distinctions.

SPC vs. PVC: Traditional PVC boards are made primarily from plastic, which provides flexibility but less rigidity. In contrast, SPC board integrates stone powder into the core, giving it enhanced strength and resistance to deformation under pressure. This makes SPC more stable in environments with fluctuating temperatures and humidity.

SPC vs. WPC: WPC stands for Wood Plastic Composite. WPC boards combine plastic with wood fibers, offering a natural look and feel. However, WPC can be more susceptible to moisture absorption compared to SPC. Because SPC board contains no organic fibers, it is less likely to swell or warp in wet environments, making it suitable for kitchens, bathrooms, and basements.

These differences highlight why many builders and homeowners prefer SPC board for specific applications that demand stability and moisture resistance.

An SPC board is a versatile material that combines the properties of stone and plastic to deliver strength, stability, and resistance to environmental challenges. Made from limestone powder, PVC, and stabilizers, it offers a layered structure that supports durability and visual appeal. Compared with traditional PVC and WPC boards, SPC board stands out for its rigidity, moisture resistance, and suitability for a wide range of applications.

As construction and design trends continue to evolve, SPC board provides a practical solution for flooring, wall panels, and other interior uses. Its balanced composition and reliable performance explain its growing presence in both residential and commercial projects.

Español

Español عربى

عربى русский

русский