Bamboo wood fiber panel is increasingly gaining popularity in the furniture, construction, and interior design industries. As sustainable materials become more important, many people are curious about how bamboo wood fiber panel differs from more traditional materials such as MDF (medium-density fiberboard) or plywood. Understanding these differences can help manufacturers, designers, and consumers make informed decisions when selecting materials for their projects.

Composition and Material Source

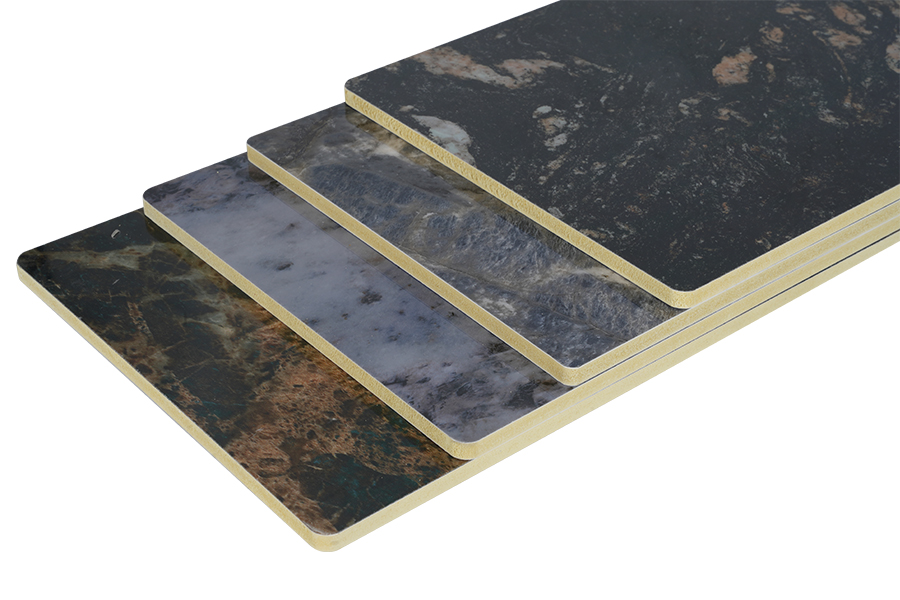

One of the key differences between bamboo wood fiber panel and MDF or plywood lies in the material composition. Bamboo wood fiber panel is made primarily from bamboo fibers, which are processed and bonded together using adhesives under heat and pressure. The result is a dense, uniform board that retains some of the natural properties of bamboo, including its strength and eco-friendly qualities.

MDF, in contrast, is produced from softwood or hardwood fibers combined with synthetic resins and wax. While it provides a smooth, even surface ideal for painting and finishing, it relies on more processed wood and chemical binders. Plywood is constructed by layering thin sheets of wood veneer in alternating grain directions, bonded together with adhesive. This cross-laminated structure gives plywood its distinctive strength and stability but differs from the uniform texture of bamboo wood fiber panel.

Strength and Durability

In terms of strength, bamboo wood fiber panel offers a unique balance. The natural properties of bamboo provide higher tensile strength and hardness compared to MDF, making it less prone to sagging under weight. Compared to plywood, bamboo wood fiber panel may have a more uniform density, which can result in a smoother finish and better performance when cutting or shaping the board. However, plywood typically provides superior resistance to bending and warping in larger panels due to its layered structure.

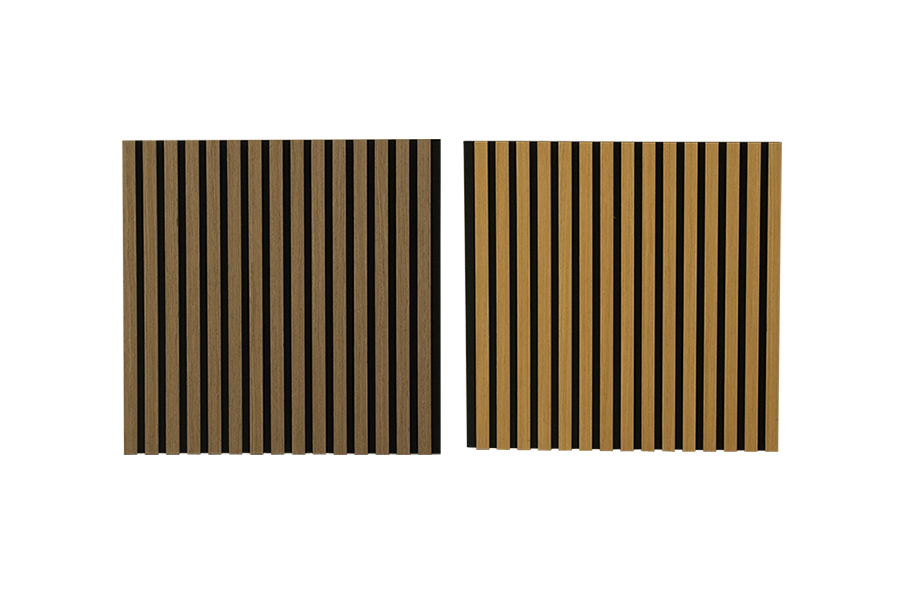

Workability and Finishing

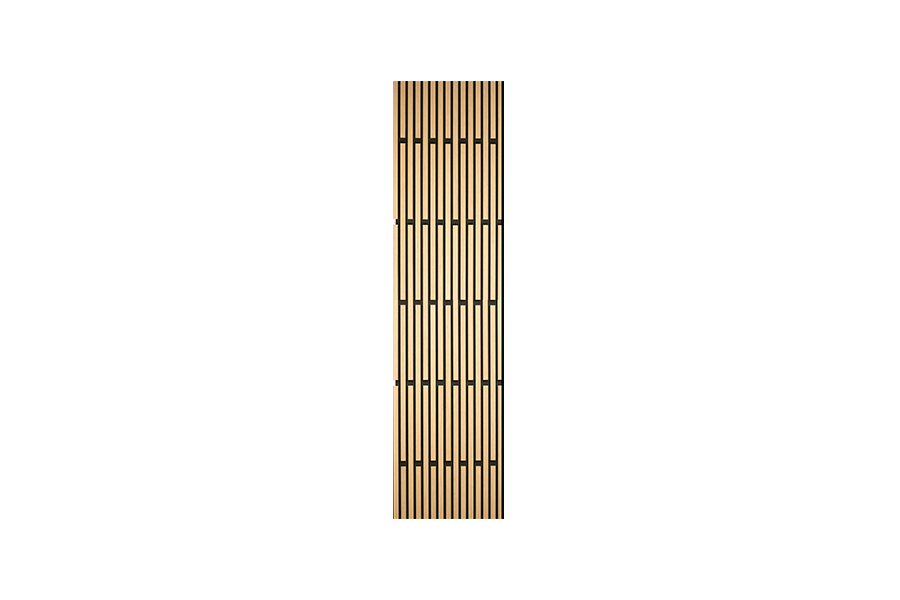

Bamboo wood fiber panel is relatively easy to work with using standard woodworking tools. It can be cut, drilled, and shaped with minimal splintering, similar to MDF. Its smooth surface also allows for effective painting, laminating, or veneering. MDF is also very easy to machine and is preferred for applications requiring precise detailing or intricate designs. Plywood, on the other hand, may require more careful handling during cutting to prevent splintering along the veneer layers.

Environmental Considerations

One of the main advantages of bamboo wood fiber panel over MDF and plywood is its environmental impact. Bamboo is a rapidly renewable resource that grows much faster than most traditional trees, making bamboo wood fiber panel a more sustainable choice. Additionally, bamboo wood fiber panel often contains fewer synthetic chemicals than MDF, which may contribute to lower formaldehyde emissions and improved indoor air quality. Plywood can also be environmentally friendly if sourced from certified forests, but its production still involves more energy-intensive processes.

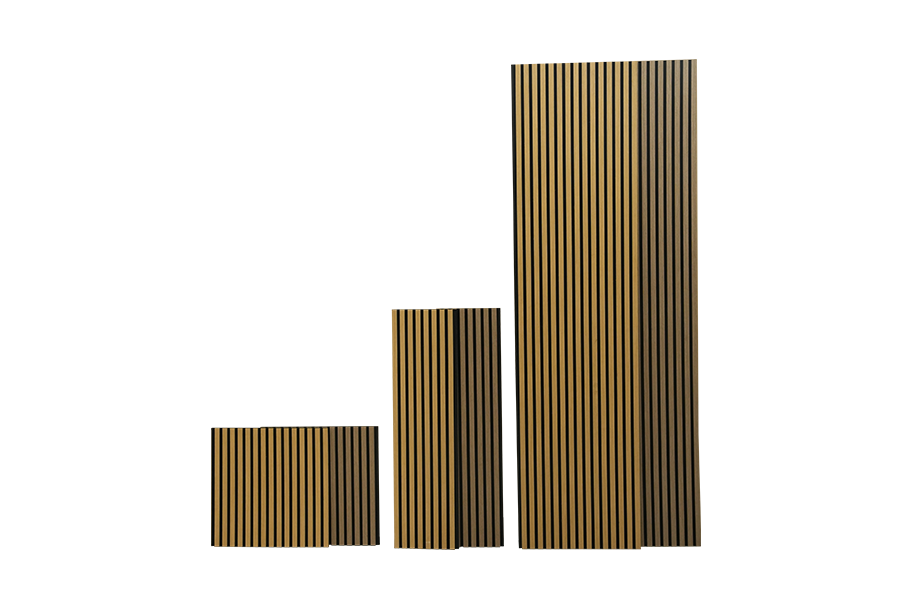

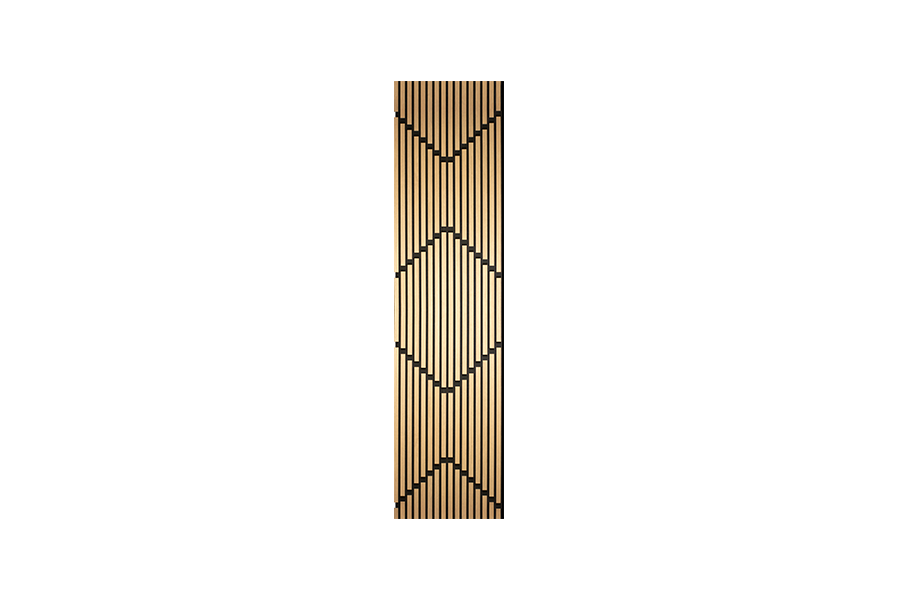

Applications and Use Cases

Bamboo wood fiber panel can be used in a wide range of applications, including furniture, cabinetry, flooring underlayment, and interior wall panels. Its combination of strength, smooth finish, and sustainability makes it suitable for both residential and commercial projects. MDF is often chosen for decorative furniture, moldings, and cabinetry where a flawless painted surface is desired. Plywood remains popular for structural applications, subflooring, and areas requiring high load-bearing capacity.

Bamboo wood fiber panel differs from MDF and plywood in composition, strength, workability, and environmental impact. While MDF offers smooth surfaces and ease of machining, and plywood provides layered strength and stability, bamboo wood fiber panel presents a sustainable, durable, and versatile alternative. Choosing the right material depends on the specific needs of a project, but bamboo wood fiber panel stands out for its natural properties, eco-friendliness, and adaptability in modern design.

Español

Español عربى

عربى русский

русский