An SPC Board, or Stone Plastic Composite Board, is a versatile material that combines durability with aesthetic appeal. Constructed from natural stone powder, PVC, and stabilizers, it forms a rigid yet lightweight core that resists impact. The decorative vinyl surface mimics wood, stone, or other materials, providing visual appeal without compromising performance.

This innovative combination allows SPC Boards to be used in residential, commercial, and industrial settings. Consulting a professional SPC Board Manufacturer can help identify the right type and thickness for each application, ensuring long-term performance and design compatibility.

Section 1: Key Advantages of SPC Board

- Durability and Resistance

SPC Boards withstand heavy foot traffic and daily wear, making them suitable for high-use spaces such as offices, retail stores, and factories. They are waterproof and moisture-resistant, preventing swelling or warping in kitchens, bathrooms, and other damp areas.

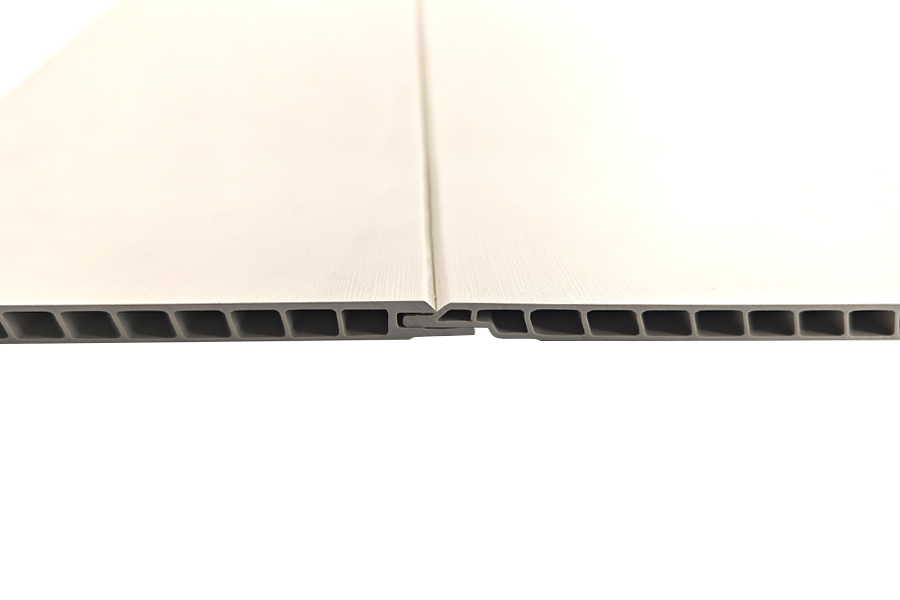

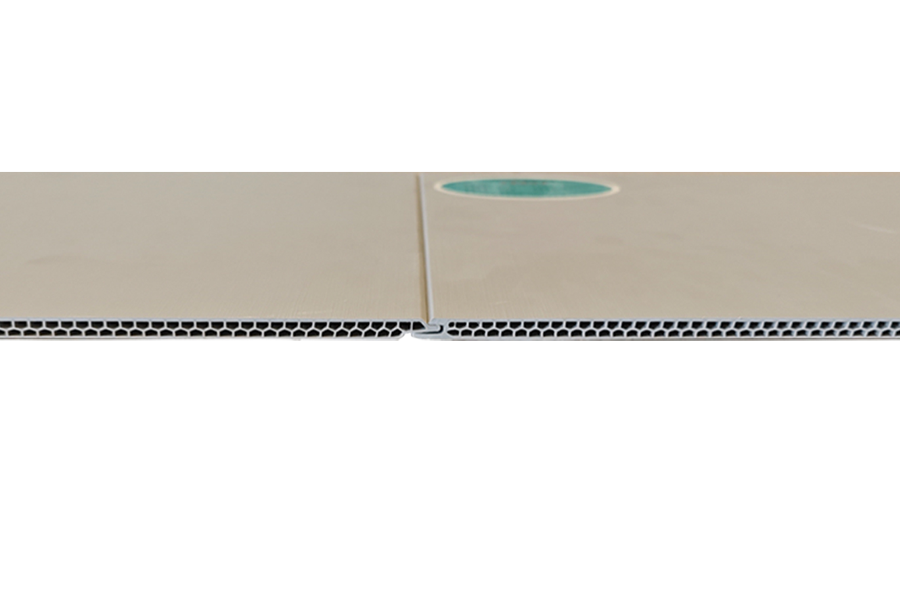

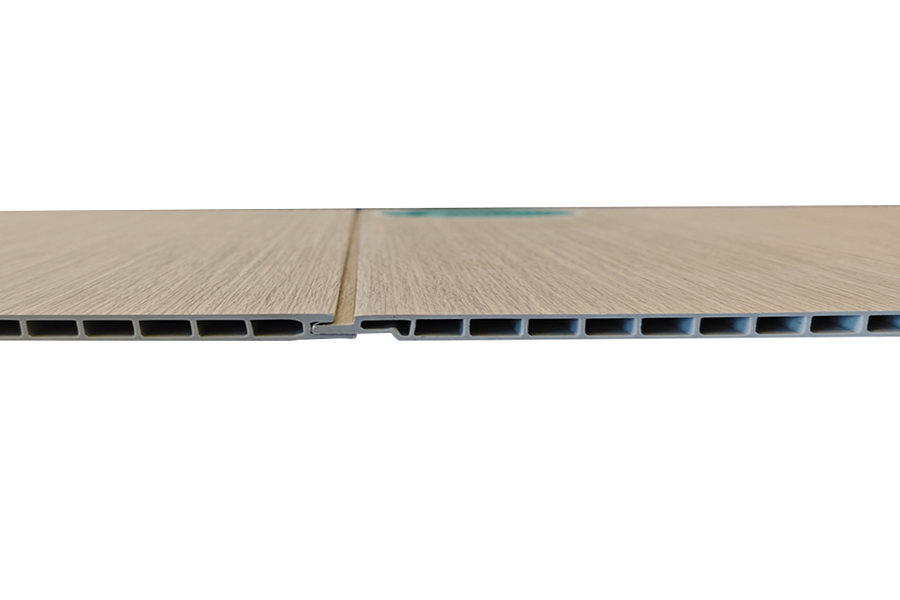

- Ease of Installation

The lightweight core and click-lock systems simplify installation. Many spaces benefit from a quick, hassle-free setup without specialized tools or extensive labor. A reliable SPC Board Manufacturer can provide guidance on installation patterns and alignment to maximize both appearance and functionality.

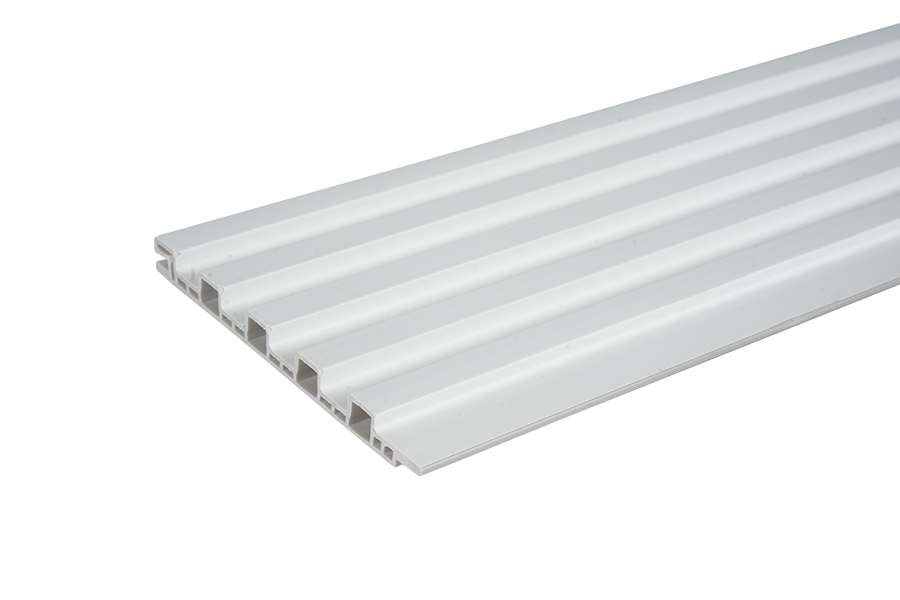

- Sound Insulation and Comfort

SPC Boards provide natural sound absorption, reducing noise transmission between floors and rooms. This property is particularly valuable in multi-story buildings, apartment complexes, or commercial offices, creating a quieter and more comfortable environment.

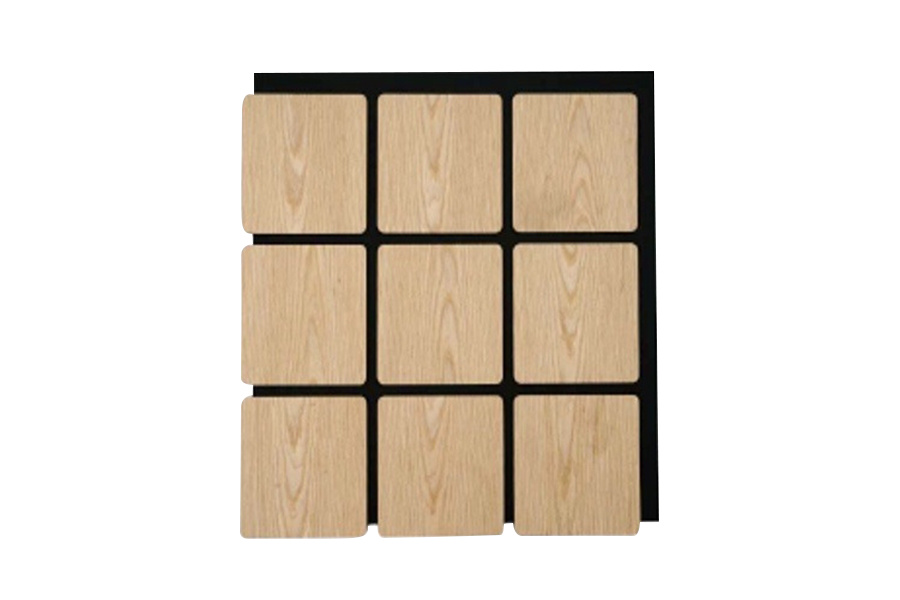

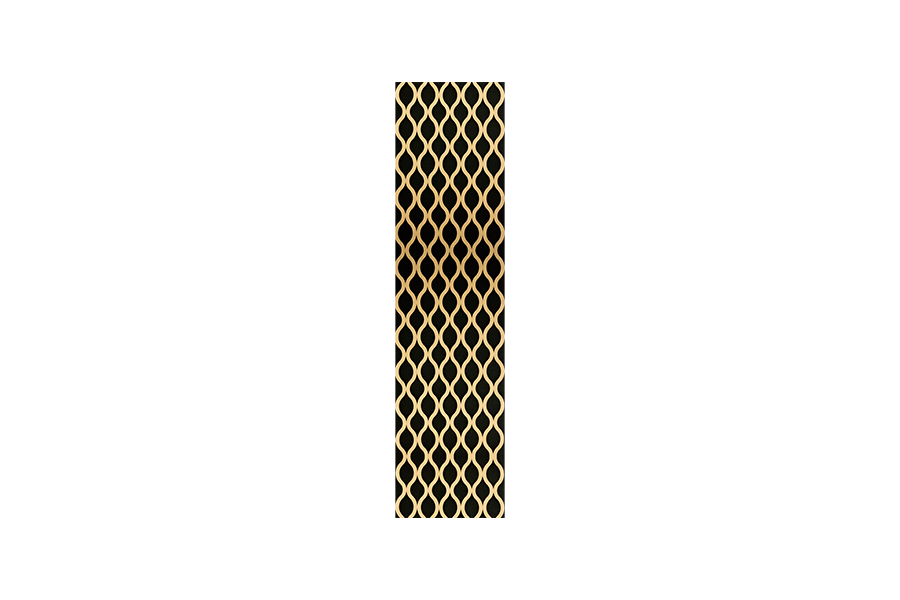

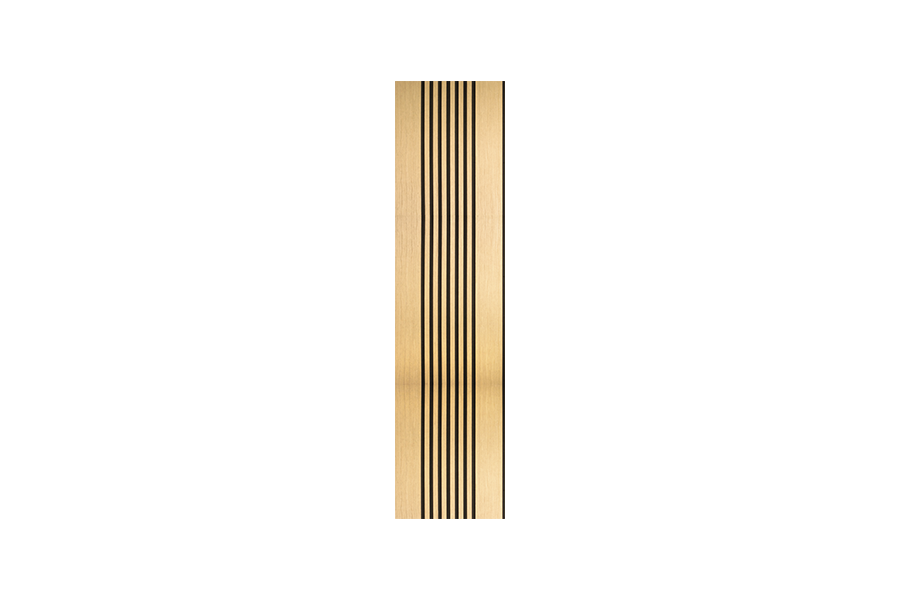

Section 2: Design Flexibility and Aesthetics

One of the appealing features of the SPC Board is its wide range of colors, textures, and finishes. From classic wood grains to contemporary stone looks, these boards can complement any interior style. The vinyl layer not only protects the core but also maintains its visual quality over time, resisting scratches and stains.

By working with a trusted SPC Board Manufacturer, designers and builders can select the right patterns and finishes for a project. The combination of functionality and aesthetics allows SPC Boards to serve both practical and decorative purposes.

Section 3: Applications Across Environments

- Residential Spaces

SPC Boards are ideal for living rooms, kitchens, and bathrooms, where durability, moisture resistance, and style are essential. Homeowners benefit from easy cleaning and low maintenance, as the boards do not require refinishing or sealing.

- Commercial Use

Retail stores, restaurants, and offices often face heavy foot traffic and noise. SPC Boards withstand wear while providing sound insulation and a professional look. Consultation with an SPC Board Manufacturer can help businesses select boards that meet performance requirements while enhancing brand aesthetics.

- Industrial Settings

Warehouses and factories use SPC Boards for walls and floors due to their impact resistance and chemical tolerance. The boards also simplify maintenance in areas where hygiene and durability are priorities.

Section 4: Maintenance and Long-Term Considerations

Maintaining SPC Boards is straightforward—regular cleaning with soap and water is usually sufficient. Unlike traditional wood flooring, they do not require sanding or sealing. Their resistance to moisture, wear, and chemicals ensures a long-lasting surface that continues to look appealing.

Engaging with a reputable SPC Board Manufacturer can guide on choosing thickness, finishes, and installation methods that suit specific needs. Proper planning and professional advice ensure SPC Boards deliver both functional and visual benefits for years to come.

Español

Español عربى

عربى русский

русский