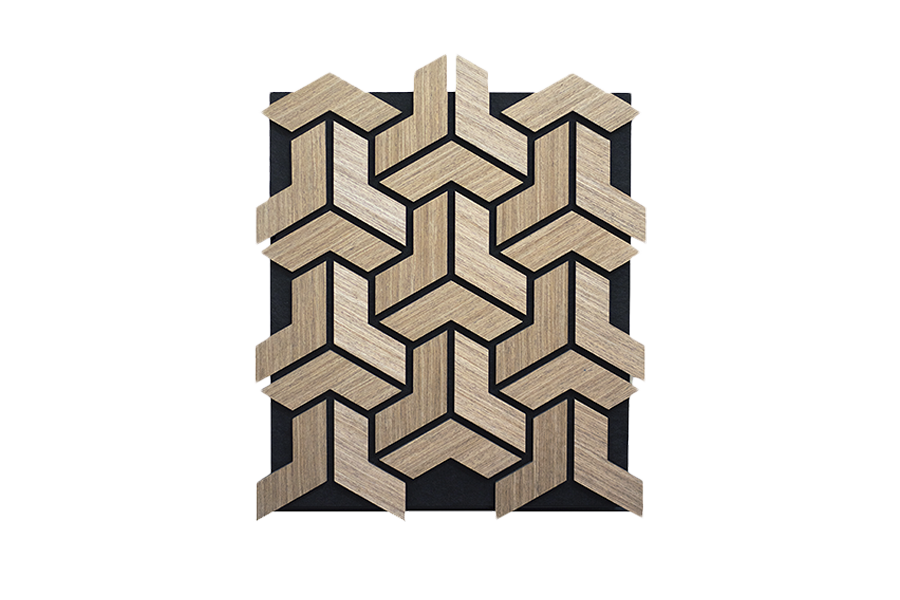

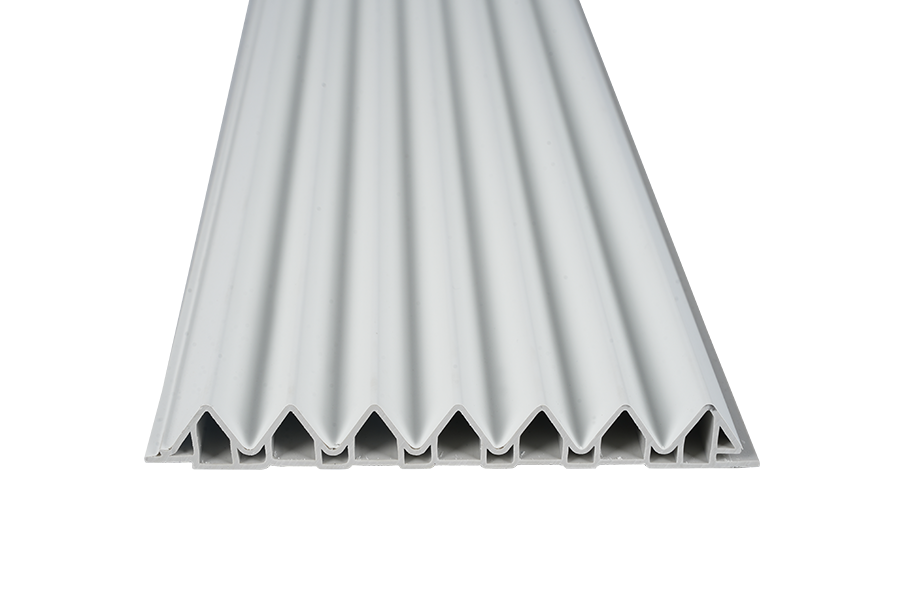

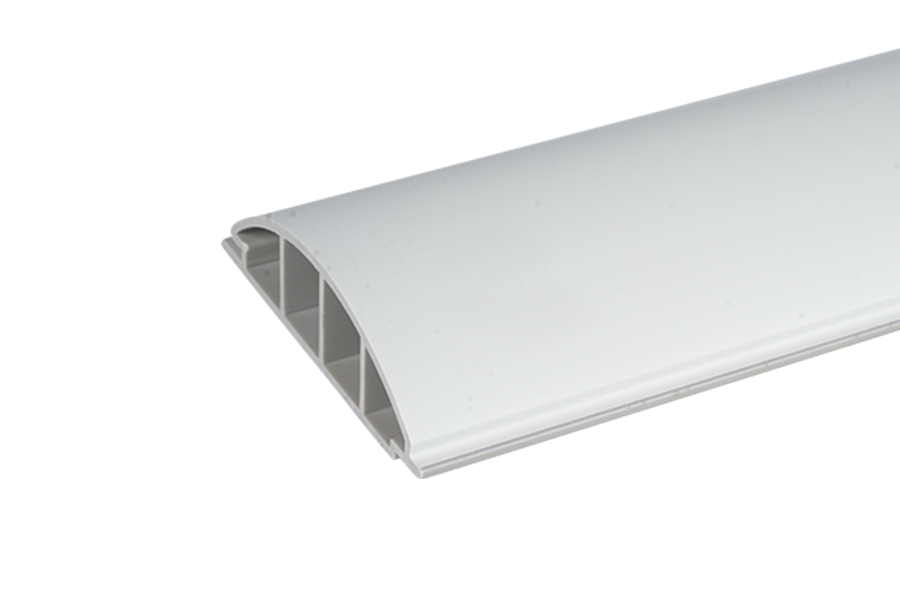

The question of environmental impact is at the forefront of modern construction and design. As we become more conscious of our choices, it’s natural to scrutinize the materials we bring into our homes and workplaces. When considering innovative materials like Stone Plastic Composite panels, a common and important question arises: Is the SPC panel truly an environmentally friendly choice? The answer is nuanced, but when produced with intention, the SPC panel presents several compelling environmental advantages that extend beyond its immediate functionality.

A Foundation of Recycled Content and Resource Efficiency

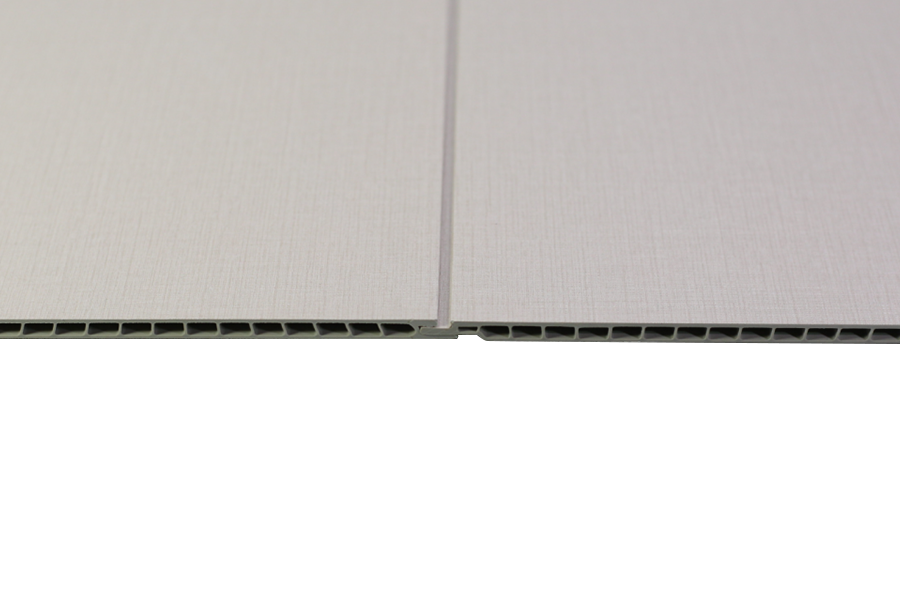

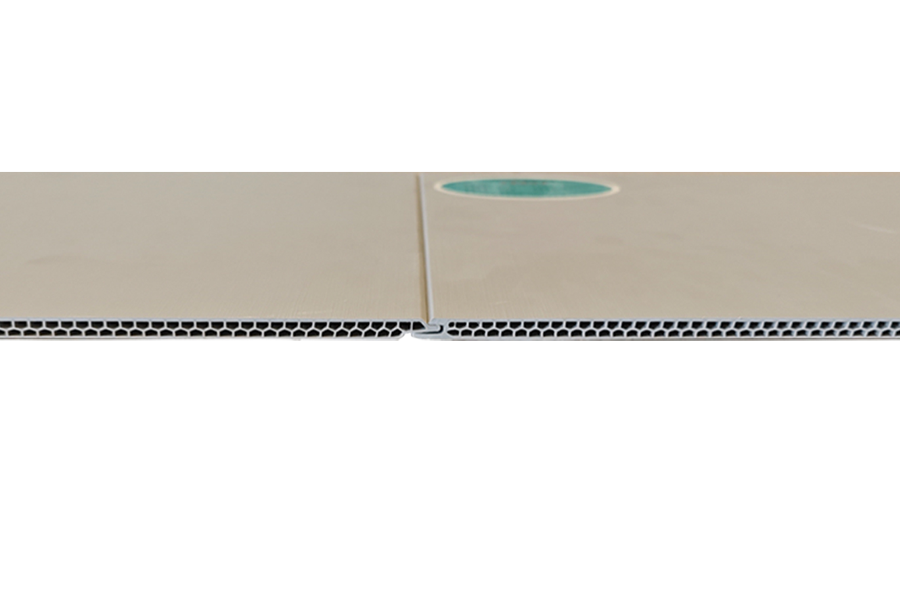

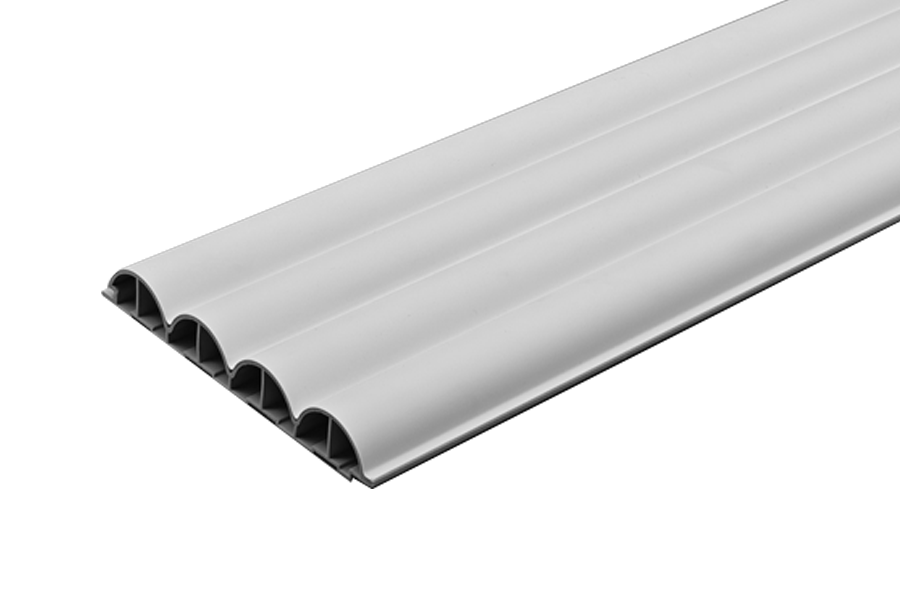

A significant aspect of the SPC panel's environmental story begins with its composition. A reputable SPC panel Manufacturer will often integrate a substantial percentage of recycled PVC into this mix. This practice diverts plastic waste from landfills and reduces the reliance on virgin plastic resins, which have a higher carbon footprint. Furthermore, the production of an SPC panel is generally less resource-intensive than that of many natural materials. It does not involve the forestry impact of hardwood or the quarrying energy required for stone tiles. The efficiency of the manufacturing process itself, which produces a durable product with waste, adds to its favorable resource profile.

Longevity and Durability: The Unsung Heroes of Sustainability

Perhaps the environmental argument for a well-made SPC panel is its durability. A product that lasts for decades inherently has a lower long-term environmental impact than one that needs frequent replacement. The SPC panel is known for its resistance to moisture, scratches, and wear. This longevity means that installations do not need to be replaced as often, conserving raw materials and reducing the energy and waste associated with manufacturing and installing new materials. For many, the answer is a clear yes, as durability is a cornerstone of sustainable design. The role of the SPC panel Manufacturer is critical here; consistent control ensures that this durability is a reliable feature across production batches.

Indoor Air and Low Emissions

A crucial and often personal concern for homeowners is indoor air. The materials in our living spaces can off-gas volatile organic compounds, which may affect health and comfort. A responsible SPC panel Manufacturer does this directly. Through stringent raw material selection and adherence to strict international standards. Many products are certified by independent bodies, ensuring they contribute to healthier indoor environments. When evaluating an SPC panel, looking for these certifications provides tangible proof of a commitment to environmental and occupant well-being. This focus on indoor air is a vital part of the product's overall environmental responsibility.

End-of-Life Considerations and Recyclability

The environmental conversation must also include what happens at the end of a product's life. While recycling programs for SPC panel products are not as ubiquitous as those for some single-material products, the inherent recyclability of the material is a positive attribute. The stone-plastic composite can, in theory, be ground down and reprocessed. The industry is moving towards creating more circular systems for these materials. When compared to products that in landfills and do not decompose, or that release harmful substances as they break down, the inert nature of an SPC panel is a relative advantage. The forward-thinking SPC panel Manufacturer invests in research to improve both the recycled content in new panels and the recyclability of old ones.

The environmental friendliness of an SPC panel is closely tied to the practices of the SPC panel Manufacturer. By choosing a manufacturer committed to using recycled content, ensuring low emissions, and producing exceptionally durable products, specifiers and homeowners can make a choice that aligns with environmental considerations.

Español

Español عربى

عربى русский

русский