SPC board has become a reliable material for both building and renovation work. Users today want flooring and wall solutions that look good, last long, and are easy to maintain. SPC board answers these needs with its rigid core structure and decorative surface, offering a balance of durability and visual appeal. Many buyers turn to experienced SPC board manufacturers to help them meet project requirements without adding complexity.

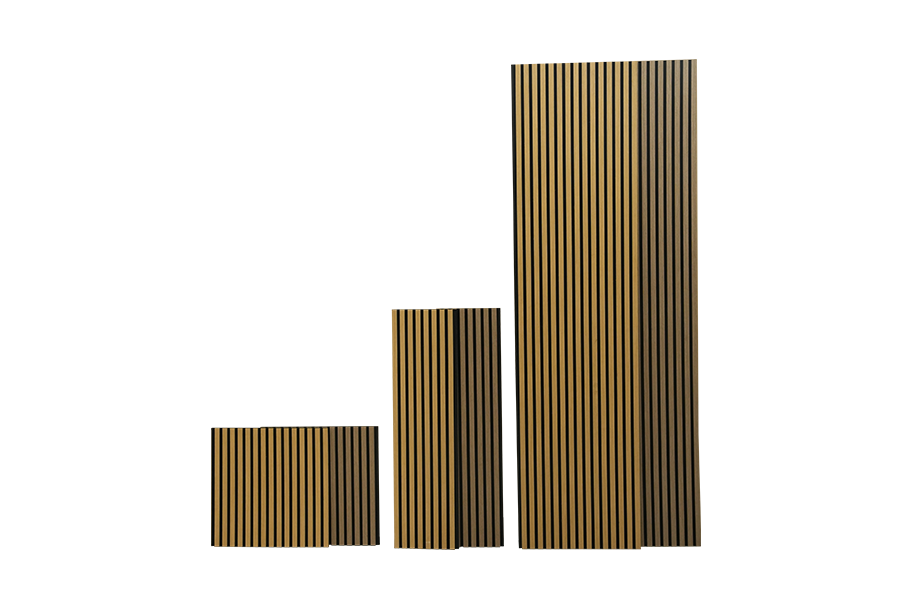

1. Understanding SPC Board Structure

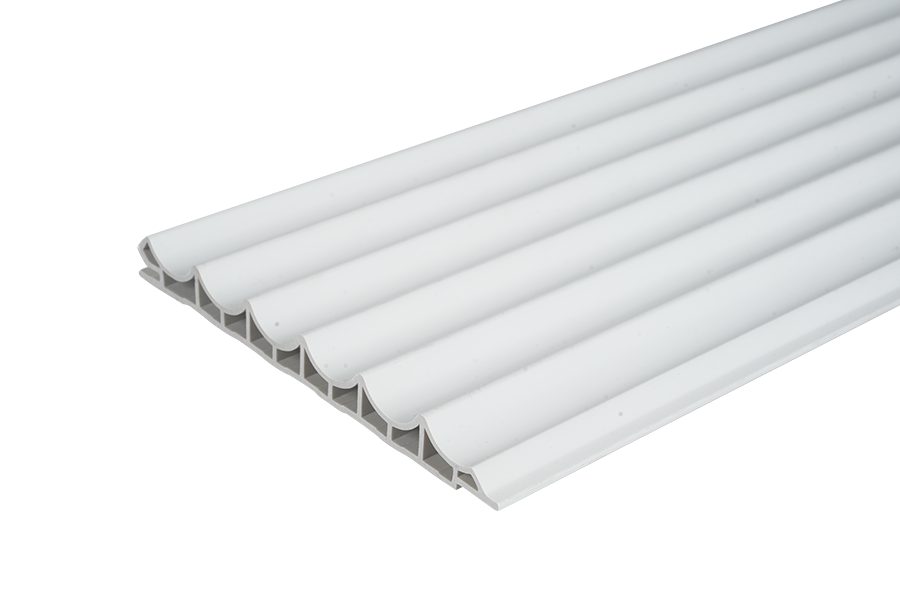

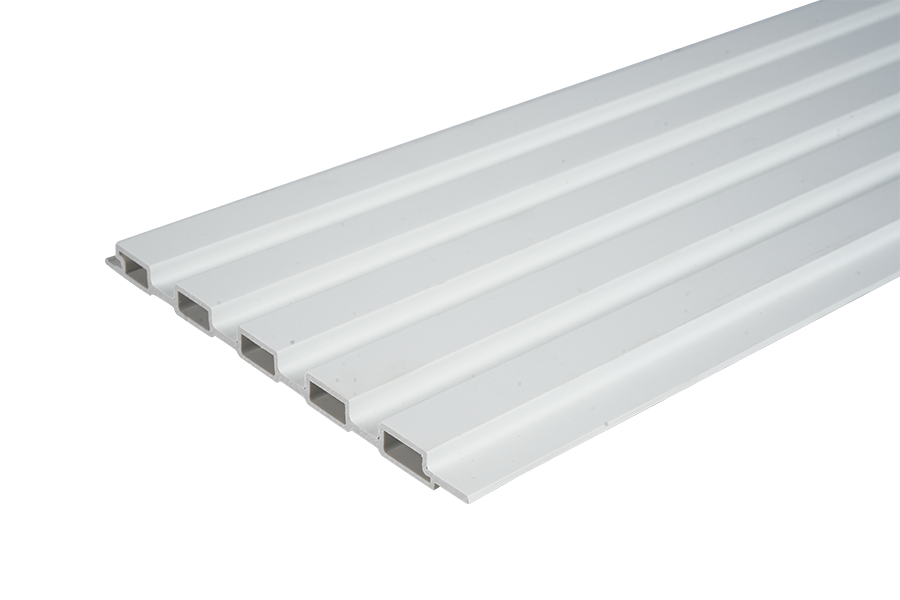

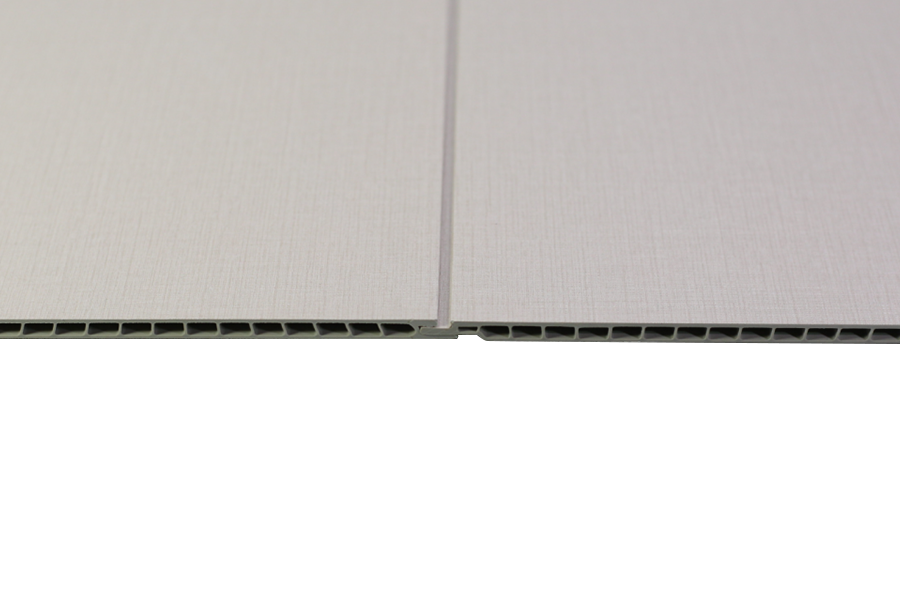

The SPC board is made from stone powder blended with PVC and stabilizers. This combination gives the board a strong core that resists impact and stays stable even when installed across wide areas. The top vinyl layer brings design flexibility, making it possible to achieve wood-like or stone-like surfaces without the upkeep associated with natural materials. This structure supports both function and style, two concerns often raised by architects, contractors, and homeowners.

2. Why the SPC Board Has Become A Popular Choice

Users turning to the SPC board often focus on the same pain points: durability, installation time, and long-term maintenance. The material addresses these concerns in several ways:

- Reliable Durability

The SPC board is built to handle regular use in busy spaces. Its rigid core resists dents and maintains stability, making it suitable for areas with frequent foot traffic. Since it is waterproof, the board performs well in kitchens, bathrooms, and entryways where spills or humidity can cause damage to other materials.

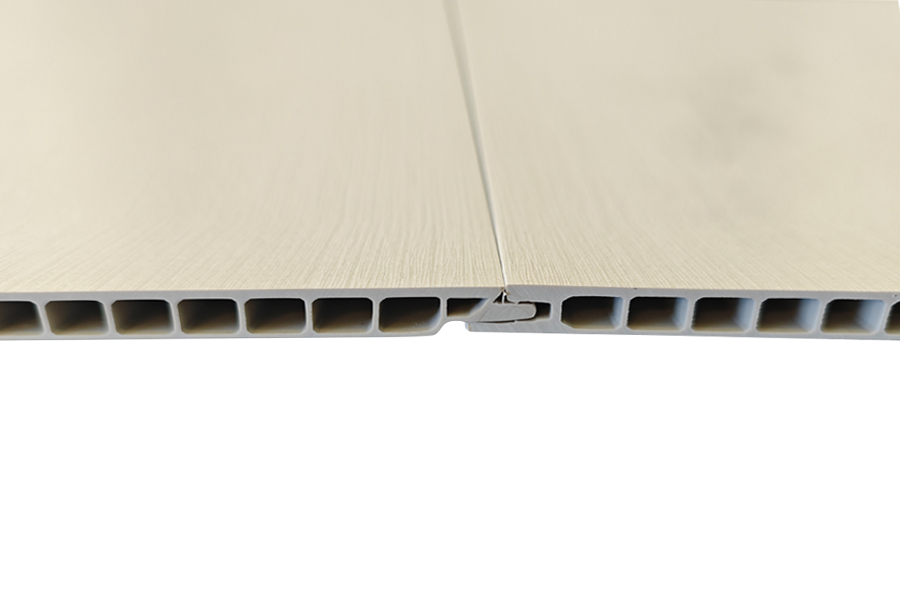

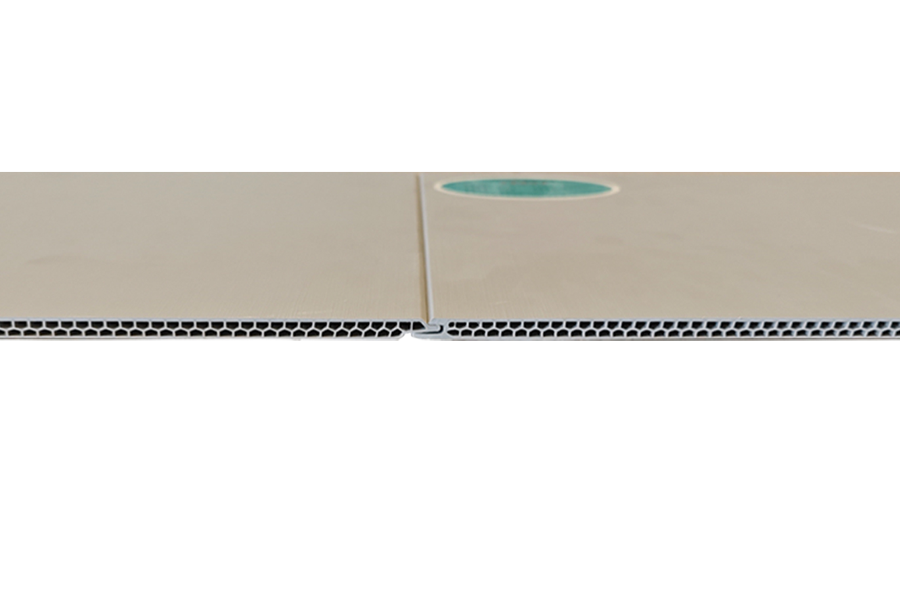

- Straightforward Installation

Many projects today require a quick turnaround. SPC board supports this need with its lightweight design and click-lock edges, which help installers reduce labor effort. Contractors using this system appreciate the predictable workflow and the reduced chance of installation errors.

- Versatile Applications

SPC board works in homes, commercial buildings, and even certain industrial settings. From living rooms to retail stores and office corridors, it offers consistency in appearance without sacrificing performance. Interior designers often select it because the surface designs pair well with a broad range of styles.

- Low Maintenance Requirements

Users do not need special products to maintain the SPC board. Regular cleaning with simple soap and water keeps surfaces in good condition. Since the board does not need polishing or sealing, facility managers can reduce ongoing maintenance time.

- Sound And Environmental Benefits

The SPC board provides sound insulation, which helps reduce noise transfer between rooms. This is helpful in multi-unit residences, open-plan offices, or spaces where acoustic comfort matters.

Its recyclable composition also supports buyers seeking environmentally conscious materials. Many SPC board manufacturers work to maintain production processes that release fewer VOCs, making SPC board a practical choice for improving indoor air conditions.

3. How the SPC Board Is Used Across Different Sectors

- Residential Spaces

Homeowners choose SPC board for living rooms, bedrooms, kitchens, and bathrooms. The waterproof core makes it suitable for moisture-prone areas, and the wide range of textures allows users to match their interior style.

- Commercial Environments

Shops, offices, and restaurants require materials that stay visually appealing while handling heavy daily use. SPC board provides a stable surface that resists wear, helping businesses maintain a clean, professional appearance.

- Industrial Uses

Some industrial facilities adopt SPC board for wall coverings or certain flooring areas where chemical resistance and easy cleaning are important. These applications benefit from the board's durability and smooth surface.

SPC board offers durability, straightforward installation, design flexibility, and simple maintenance. These qualities explain why many professionals and property owners choose it for both new construction and renovation projects. With support from experienced SPC board manufacturers, buyers can find solutions that match both performance expectations and project design goals.

Español

Español عربى

عربى русский

русский